In the field of surgery, the fight against bacterial infections is a big problem. An innovative surgical implant developed by researchers could change the game. The latter has demonstrated remarkable efficacy in the laboratory, eliminating 87% of the bacteria responsible for staphylococcal infections while maintaining robustness and compatibility with surrounding tissues.

The results of this research could ultimately improve infection control in many common surgeries, such as hip and knee replacements. Indeed, bacterial colonization of implants is one of the main causes of implant failure and postoperative complications.

” Infection is a problem for which we do not have a solution “, he indicated Amit Bandyopadhyay, lead author of the paper and a professor at Washington State University. ” In most cases, the implant has no defense against infection. We need to find something where the material of the device itself provides some resistance – more than just providing drug-based infection control. »

A new generation of implants

The titanium materials used for hip and knee replacements and other surgical implants were developed more than 50 years ago and are not well suited to overcoming infections. Although surgeons often treat prophylactically with antibiotics, a life-threatening infection can occur immediately after surgery or weeks or even months later as a secondary infection.

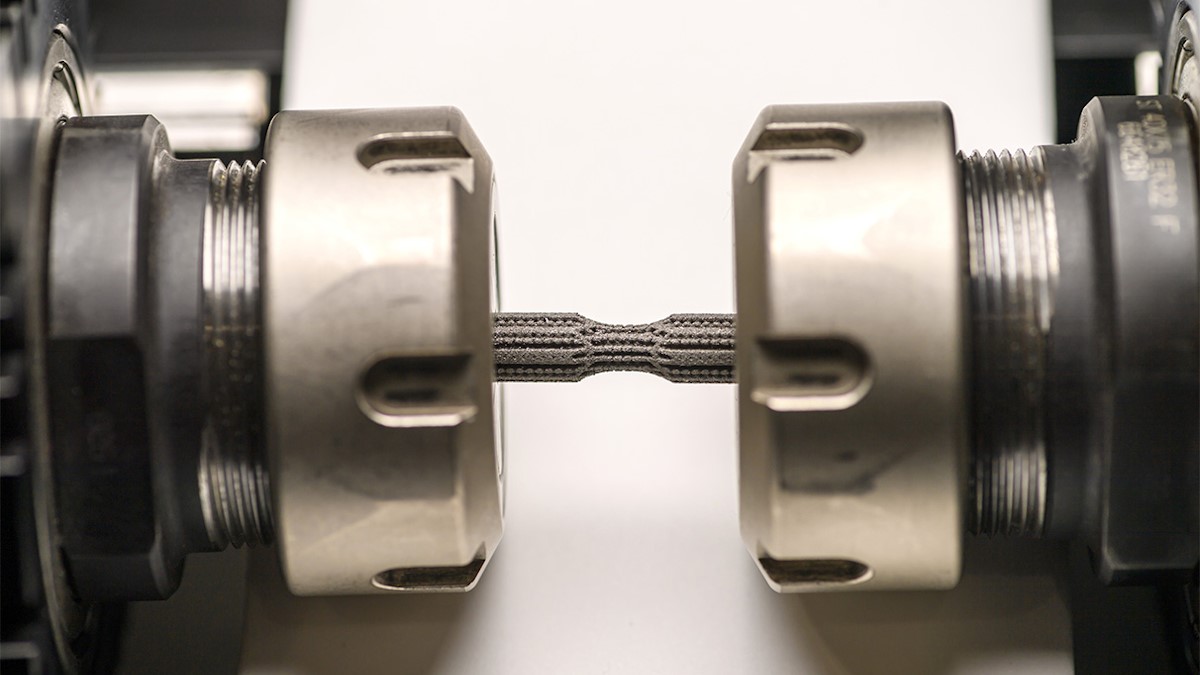

Using 3D printing technologyWashington State University researchers added 10 percent tantalum, a corrosion-resistant metal, and 3 percent copper to a titanium alloy typically used in implants. When the bacteria come into contact with the copper surface of the material, almost all of their cell walls rupture. At the same time, tantalum supports the healthy growth of cells with the surrounding bone and tissue, which leads to accelerated healing of the patient.

Towards continuous improvement

The researchers are continuing their work and hope to improve the bacterial mortality rate to more than 99% without compromising tissue integration. They also want to make sure the materials perform well under real-world loading conditions that patients might use, such as hiking in a knee replacement.

Synthetic

This research paves the way for a new generation of surgical implants capable of effectively fighting bacterial infections. With a combination of robustness, compatibility with surrounding tissues and antibacterial properties, these implants could revolutionize the field of surgery.

For better understanding

1. What is the goal of this innovative surgical implant?

The goal of this implant is to effectively combat bacterial infections, especially those caused by staphylococci, while maintaining robustness and compatibility with the surrounding tissues.

The researchers used 3D printing technology to add 10% tantalum and 3% copper to a titanium alloy typically used in surgical implants.

3. What are the advantages of adding tantalum and copper?

Tantalum promotes healthy cell growth with the surrounding bone and tissue, while copper causes bacterial cell walls to burst, eliminating almost all bacteria in contact with the implant surface.

4. What is the rate of elimination of bacteria with this implant?

The implant demonstrated remarkable effectiveness in the laboratory, eliminating 87% of the bacteria responsible for staphylococcal infections.

5. What are the prospects for improving this implant?

The researchers want to improve the bacterial mortality rate to more than 99% without compromising tissue integration and ensure that the materials perform well under real-world use conditions.

The main lesson

| Description |

|---|

| An innovative implant to fight bacterial infections |

| Use of 3D printing technology for implant design |

| Adding 10% tantalum and 3% copper to a titanium alloy |

| Elimination of 87% of the bacteria responsible for staphylococcal infections in the laboratory |

| Tantalum promotes healthy cell growth with surrounding bone and tissue |

| Copper causes bacterial cell walls to break down |

| Ongoing research to improve bacteria kill rate to over 99% |

| Evaluation of material properties under conditions of real use |

| Potential to improve infection control in many common surgeries |

| Further work is needed to ensure the effectiveness and performance of the implant |

Reference

Caption Main illustration: WSU researchers tested the fatigue resistance of a new 3D printed material. Photo by WSU Photo Services

Links in this article are taken from the International Journal of Extreme Manufacturing.

(writing)